Nationwide Engineering

for Commercial and Utility Scale solar + Storage Projects

Solar & Energy Storage Engineering Services

Value Engineering Tips | Solar + Storage See More

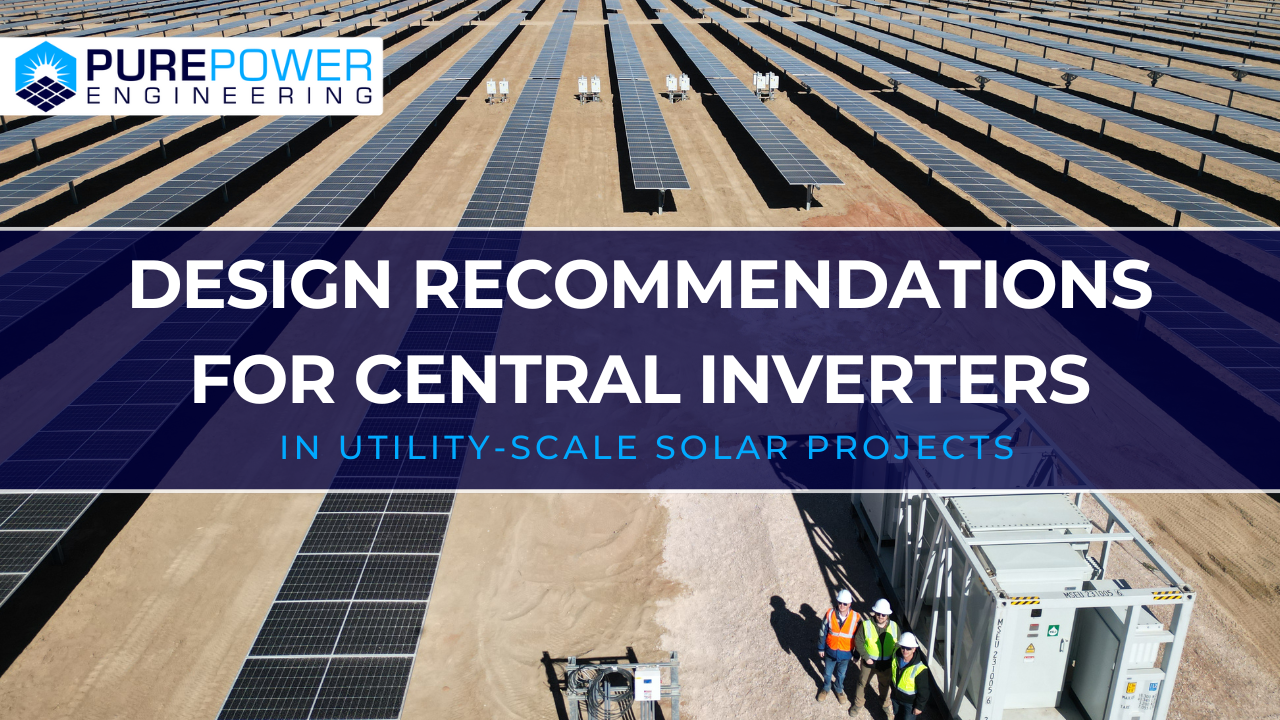

Design Recommendations for Central Inverters in Utility-Scale Solar Projects

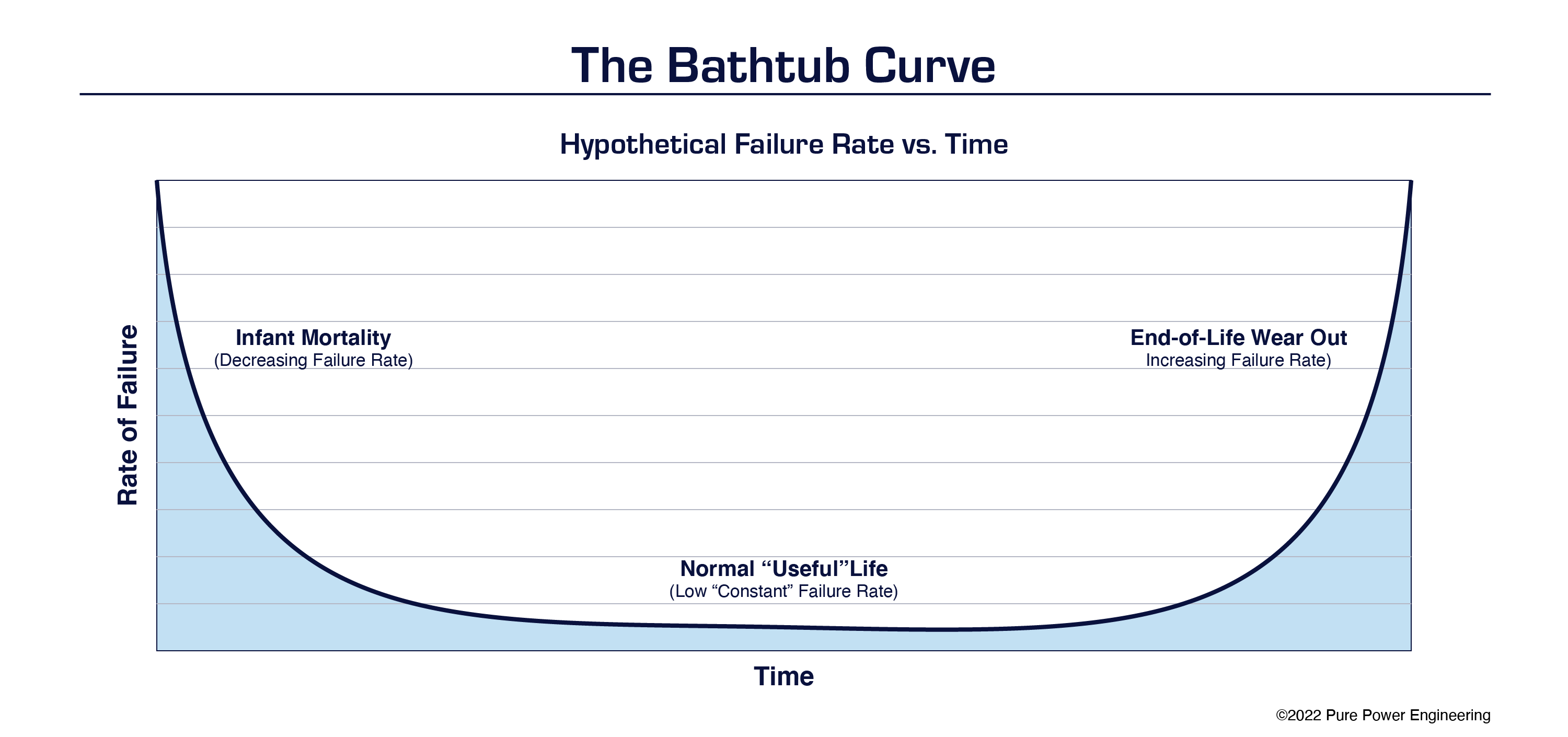

When designing utility-scale solar energy projects, optimizing central inverters is a crucial aspect that project developers, EPCs, and stakeholders often overlook. The strategic placement and design of central inverters plays a significant role in..

Lessons from the Early Adopters

Pure Power has provided clients with professional services for more than a decade, including electrical, structural, and mechanical engineering, energy modeling, project development support, and PV plant performance analysis and reporting. The..

Companies continually seek ways to maximize efficiency, reduce costs, and streamline their operations in the increasingly competitive solar industry. A common strategy many firms adopt involves outsourcing engineering services despite the presence..

In the competitive world of solar engineering, the allure of saving money on upfront costs might seem like a wise choice for many EPCs. However, deciding to opt for a lower-cost overseas firm often comes with hidden costs and risks that can..

Contact Us

The Latest from Pure Power View All

When designing utility-scale solar energy projects, optimizing central inverters is a crucial aspect that project developers, EPCs, and stakeholders often overlook. The strategic placement and design of central inverters plays a significant role in...

Continue Reading →Pure Power has provided clients with professional services for more than a decade, including electrical, structural, and mechanical engineering, energy modeling, project development support, and PV plant performance analysis and reporting. The...

Continue Reading →Companies continually seek ways to maximize efficiency, reduce costs, and streamline their operations in the increasingly competitive solar industry. A common strategy many firms adopt involves outsourcing engineering services despite the presence...

Continue Reading →.png)

%20(1)-1.png)